Corporate

We in the Press

Services

Dosb Layout Plan

Drinking Water Conditioning And Disinfection Plant

- Home Page

- Social Facilities

- Drinking Water Conditioning And Disinfection Plant

Drinking Water Conditioning And Disinfection Plant

-

Administration Building

-

Central Wastewater Treatment Plant

-

Drinking Water Conditioning And Disinfection Plant

-

Vocational Training Center

-

Private DOSTEK College

-

Nursery

-

Fire Department

-

Customs Directorate

-

DOHAŞ Warehouse

-

PAU OSB District Polyclinic

-

112 Emergency Health Station

-

Pharmacy

-

TSE

-

Meeting Halls

-

Sports Facilities

-

Trade Center

-

Gendarme

-

PTT

-

Denizli OSB Mosque

-

Truck Park

Click To Close

- Home Page

- Social Facilities

- Drinking Water Conditioning And Disinfection Plant

Drinking Water Conditioning And Disinfection Plant

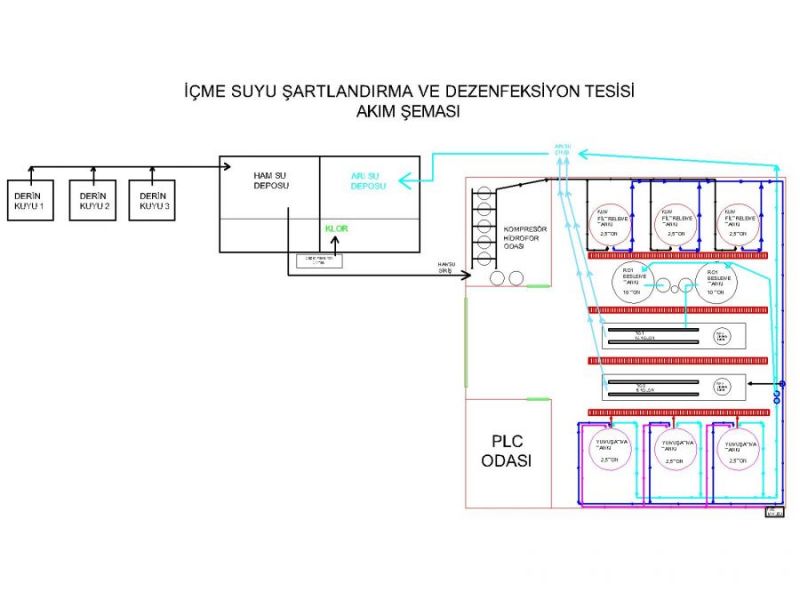

Our project of providing drinking water service, which has been longed for in our Organized Industrial Zone, has been realized with the contributions of Honaz Municipality and Iller Bank. Our facility was established on the 5th km between Pınarkent - Honaz road and was opened on January 25, 2005. Our Drinking Water Facility; It consists of Raw Water Wells, Raw Water and Soft Water Tank, Hydrophore and Compressor Unit, Sand Filters / Separator and Softening Tanks, Residual Chlorine Controlled Dosing Unit and PLC Automation Control systems.

Our raw water needs are met from 2 deep wells drilled with the protocol made by Honaz Municipality and Iller Bank. The wells have a capacity of approximately 80L / s and the hardness of the water is at 55 ° FS.

The construction of the 4.5 km long Ø300 drinking water transmission line was carried out at 250.000, - YTL with the facilities and technical staff of our Organized Industrial Zone.

DOSB Drinking water tank was built with a 200-unit, 200 YTL price, according to the Iller Bank type project, with a total volume of 1.000 m³.

Our Organized Industrial Zone site's natural gas network construction and 18 km drinking water network construction were completed on 30.06.2004, with a price of 750.000 YTL.

As a result of this project, which was carried out to 450.000.- YTL for the purpose of providing healthy drinking water service, due to the fact that the current drinking water is at 55 ° FS, the Regulation on Water for Human Consumption Purpose dated February 17, 2005 and numbered 25730 Drinking water is provided in accordance with Annex-2 Table A.

HYDROPHOR AND COMPRESSOR UNIT

In our company; At the first entrance to the system, there are 5 Grundfoss booster pumps (60 m³ / h) that pump raw water for softening and a compressor that supplies air to the system.

AUTOMATIC SAND FILTERS / SEPERATOR TANKS

3 sand filters made of AISI 304 stainless quality, each containing 2000 micron filtration precision, containing 2,500 L silica and 5,600 L empty volume, are filled with 4 - 6 bar pressure through hard water hydrophore at 55 0FS which is filled and chlorinated from our pump to the raw water tank in Honaz Municipality. Its sediment is removed by passing it through sand filters.

Sand filters backwashing is done in the time period to be determined. Backwash is done sequentially, starting with the numbers 1 sand filter, respectively. In the backwash process, the water is supplied to the tank together with air and the gravel containing SiO2 is cleaned by rotating on it. The muddy water discharged during the backwash is returned to the raw water reservoir by settling the sludge in the cyclone filter and in this way 95% of the water lost by the backwash is recovered.

WATER SOFTENING TANKS

The hard water passed through the sand filters is sent to our potable water tank by softening to 3 softening tanks of 316 L quality stainless steel with a capacity of 2,500 L Na-resin each having a capacity of 300m3 soft water in two freshening intervals from 55 FS0 raw water.

The brine pool, where the brine used for regeneration process is obtained, has a volume of 15.000 L. In regeneration process, there is 160 g salt consumption for 1L resin. 480 kg of salt is spent for regeneration of a softening tank.

All tanks in our facility are TSE certified and comply with TSE pressure vessels norms. A total of 180 m3 of water can be softened per hour in our tanks, each operating at 60 m3 / h flow rate.

NO MORE CHLORINE CONTROLLED DOSAGE UNIT

Chlorination process is done with automatic dosage chlorine pumps. Dosing automatically stops when 0.3 ppm (750 mV) of chlorine is reached, which is sufficient for the removal of living organisms and human health. Dosing starts automatically again when it is below this value. Each pool has chlorine pumps with a maximum capacity of 10L / h, with digital display, suitable for wall mounting, with flow rate adjustment signal input.

After the water in 0 FS0 coming out of the softening is chlorinated with automatic adjustment chlorine dosing pumps, the filtered raw water coming out of the filter unit is obtained with the desired mixing water with the proportional mixing valve and it is distributed with its own charm by using the difference of elevation to be used as drinking water in the factories.

All control of the system is done with PLC Automation system. Many process steps such as instant warnings, status control, how much water is softened can be controlled from the PLC device.

WATER SOFTENING AND REGENERATION PRINCIPLE IN DRINKING WATER CONDITIONING AND DISINFECTION UNIT

Softening of water with chemicals is the dissolution of the dissolved compounds in the water that give it hardness, and they are separated from the water by turning them into insoluble compounds. In our facility, water softening is done by Ion Exchange Method. Although there are many different methods in softening today, the most useful method in terms of both cost, workmanship and time is the ion exchange method. After the softening of the water, initial and final hardness determinations are made to analyze whether the hardness is removed completely or not. In water softening with ion exchangers, it is essential to remove Ca + 2 and Mg + 2 ions. It should be noted that ion exchangers have high exchange capacity, are not affected by water, require low cost in regeneration and are easy to find.

The chemical softening process can be explained by the following reaction:

Na2R + CaCO3 Na2CO3 + CaR Resin Hardness in water Hardness from water The final cause of resin removal

The regeneration process resins are regenerated when the capacity of the ion exchange resin is exceeded. In other words, the cations removed during the softening of the ion exchanger are recycled to the resin. Regeneration is performed by washing the resin with the solution of the salt containing that cation in accordance with the cation type of the resin used. Usually, resins containing Na + ion are used for cost-effectiveness and regeneration is carried out with brine.

The chemical regeneration process can be explained by the following reaction:

CaR + 2NaCl (aq) Na2R + CaCl2 Salt water First state of the resin with rinsing removed from the environment.

After the water is brought to the desired softness, finally disinfection process is started. Disinfection is the process of removing disease-causing bacteria that can be found in water. In order for a substance to be used in the disinfection process, it must be able to remove all microorganisms that may cause disease in the water, to perform disinfection in water in a limited time, not to create harmful and poisonous products in the water, and to be applied cheaply and easily.

Social Facilities

- Home Page

- Social Facilities

- Drinking Water Conditioning And Disinfection Plant